FLOWDRILL Technology

Special tools for the particle-free production of forming holes and threads

FLOWDRILL

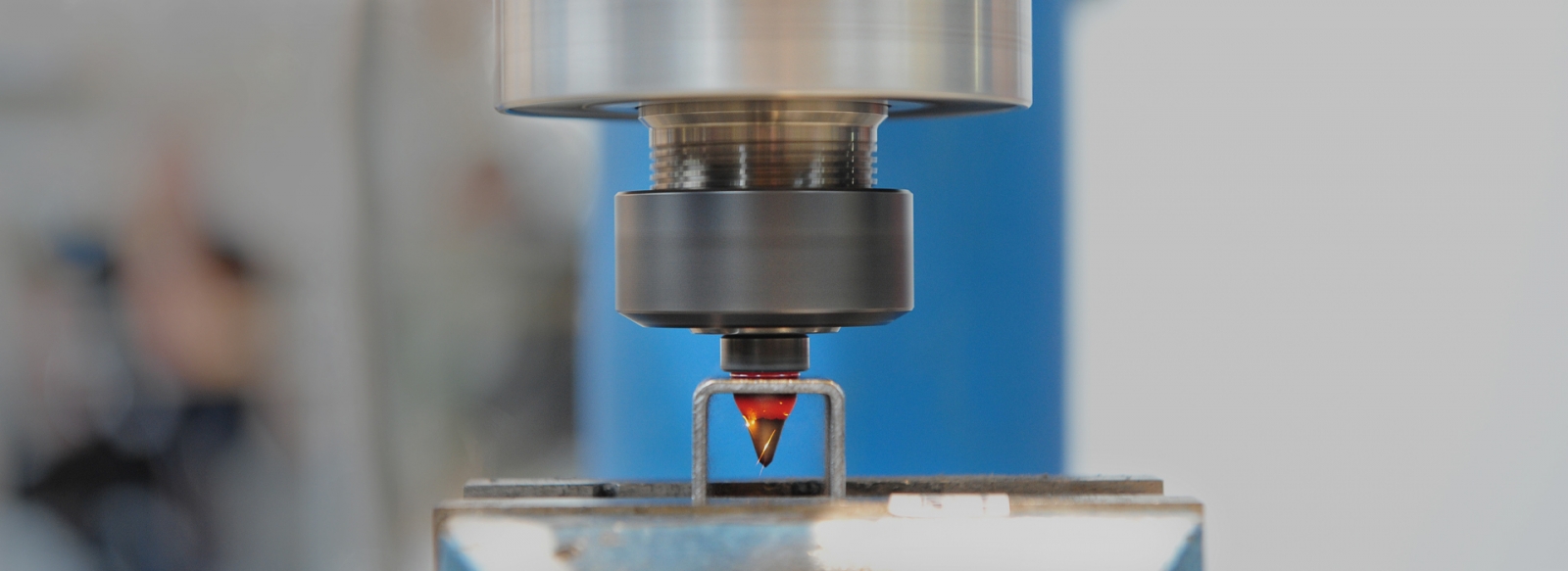

A process in which the cone is pushed against the material at high rotation speed. The axial force and high speed result in forming temperature. The tool then passes through the material and creates a cylindrical or cone housing suitable either for mounting the pin or for rolling the threads forming the taps.

ADVANTAGES OF USE

This technology can be used to produce holes with housing or threaded holes and excellent technical and strength properties.

If the designer

needs a thread with good strength or a thread in a non-accessible place (e.g. cylindrical tubes, square or rectangular profiles), the Flowdrill technology can be successfully used. In terms of the strength, durability and reliability of the thread produced in this way, it is difficult to compare. In addition, the low cost of a single-threaded hole and the possibility of incorporating this technology into an automated process are an advantageous investment with a fast return and for the designer the possibility of a unique and reliable technical solution.

- Eliminates the need of weld-on nuts.

- The tool service life in steel, with a strength of about 400 N/mm, reaches 10,000 holes.

- The housing is of very high quality and the exact hole diameter is accurate.

- It is ideal for automation.

- Tapping of threads achieves lighter structures thanks to easier assembly of parts.

- The thread bearing capacity is high, and the thread is compact without cracks.

- Significant time savings in opening forming.

- Standard table, column drills or CNC machines can be used.

- There are no splinter problems.

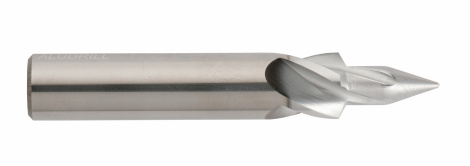

FLOWDRILL TIP TYPES

SHORT

Short active part, housing at the end of the cone.

LONG

Long active part, the bushing has a cylindrical cross-section suitable,

for example, for fitting the pipe, pin.

TRIMMED (FLAT)

The tool mills the collar of the casing pushed around the hole (a variant

for both short and long).

WITH BORING TIPS

The tool has a boring edge on the tip, which facilitates material

penetration (variants for both short and long).

SUITABLE MATERIAL

Steel up to a strength of 700 N/mm” including stainless steel, non-ferrous metals except fragile materials, light metals (Si less than 10%).

SUITABLE DRILL

Required drill power – necessary rotation speed approx. 1,400-6,000 rpm.

LUBRICATION

Due to high temperatures, it is necessary to lubricate the tool before each hole with a special lubricant (depending on the material), which is a part of the technology. The technology also includes an oil for forming taps.

CLAMPING

The Flowdrill tool is clamped in a holder composed of a Morse cone cooling turbine which prevents heat spreading into the drill spindle and clamping housing.

WE OFFER:

- Delivery of technology according to your requirements and drawing documentation

- We can offer consultation or propose a solution.

WE CAN CONDUCT TESTS BASED ON

- the type of the tool in question,

- expected shelf life,

- hole and thread production time .

Companies that use Flowdrill technology: Audi, Porsche, Keiper Recaro, Cummins, Ferrari, IBM, Fiat-Iveco, Mercedes Benz, Siemmens, Zetor among many others.

CONTACT US:

FlowDrill

-

Flowdrill - Analýza úspory nákladů

10.3 MBDownload -

Flowdrill - Beztřískové spojování

950.6 kBDownload -

Flowdrill - Flow2Go

718.5 kBDownload